Properties

-

Butt Fusion machine to joint PE, PP, PB pipes and fittings for pressure piping systems on building sites and in trenches.

-

Hydraulically operated with manual control unit.

- Temperature controller integrated in the heating element handle.

-

Including transport packaging (carton pallet); reduction clamping inserts and other accessories to be ordered separately.

BASE MACHINE

-High precision design, distortion-free and sturdy machine frame

-Good accessibility thanks to 35° inclination

-The movable (sliding) 3rd clamp allows easy and time-saving fixation of bends or tees without need of additional tools

-Clamps are hinged on the top side and tilting. Whenever necessary, the four clamps can be quickly removed

-Double-sided heating element pull-off mechanism to optimise the change over phase

-Weight: Type 160 = 22 kg, Type 250 = 47 kg, Type 315 = 53 kg

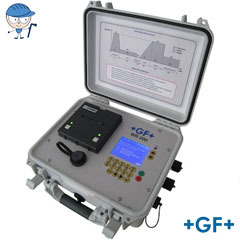

HYDRAULIC UNIT

-Compact construction with protection frame

-Precise pressure setting and fine adjusting

-Joystick operation of machine carriage

-Clearly visible, vibration-free pressure gauge with precision scaling

-Accumulator for pressure equalization during the cooling phase

-Integrated interface for welding recorder

-Max operating pressure: Type 160 = 100 bar, Type 250 - 315 = 160 bar Weight: 22 kg

PLANER

-Powerful parallel planer for single or double-sided facing of pipe ends

-Ergonomic, weight-balanced handling

-Self-locking mechanism in working position

-Safety microswitch to prevent undesired start-up

-Weight: Type 160 = 7 kg, Type 250 = 14 kg, Type 315 = 17 kg

HEATING ELEMENT

-High performance, electronically controlled heating element

-High-quality, non-stick PTFE-coating with long service life

-Temperature indicator integrated into the handle

-Weight: Type 160 = 5.5 kg, Type 250 = 8 kg, Type 315 = 10 kg

-Input power: Type 160 = 1200 W, Type 250 = 2000 W, Type 315 = 2500 W

CASE

-For safe storage of planer and heating element

-Weight: Type 160 = 4.8 kg, Type 250 = 8 kg, Type 315 = 9 kg