Properties

-

BASE MACHINE

-High precision design, distortion-free and sturdy machine frame

-Good accessibility thanks to 45° inclination

-The movable (sliding) 3rd clamp allows easy and time-saving fixation of bends or tees without need of additional tools

-Double-sided heating element pull-off mechanism to optimise the change-over phase

-Weight: Type 400 = 80 kg, Type 500 = 157 kg, Type 630 = 222 kg

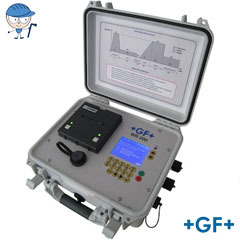

HYDRAULIC UNIT

-Compact aluminium case with innovative design

-Intuitive control panel provided with digital indication of hydraulic pressure, electronic heating element temperature controller, 2-channel welding timer

-Automatic pressure control during the cooling time

-Built-in data logger and realtime communication with mobile smartphones (at least iOS 11 or Android 7) during the welding process and fusion data download, working in combination with TOP WeldinAir mobile application

-Precise pressure setting and fine adjusting

-Push-button operation of machine carriage

-Integrated power outlets for planer, heating element

-Accumulator for pressure equalization during the cooling phase

-Max operating pressure: Type 400 = 160 bar, Type 500 - 630 = 200 bar Weight: 34 kg

PLANER

-Powerful parallel planer for single or double-sided facing of pipe ends

-Ergonomic, weight-balanced handling

-Self-locking mechanism in working position

-Safety microswitch to prevent undesired start-up

-Weight: Type 400 = 47 kg, Type 500 = 58 kg, Type 630 = 102 kg

-For Type 500 a special version is available, with enhanced performance to work with PP pipes and fittings up to d 500 mm SDR 11

HEATING ELEMENT

-High performance, electronically controlled heating element

-High-quality, non-stick PTFE-coating with long service life

-Temperature indicator integrated into the handle

-Weight: Type 400 = 16 kg, Type 500 = 26 kg, Type 630 = 51 kg

-Input power: Type 400 = 3.5 kW, Type 500= 4.0 kW, Type 630 = 8.0 kW

CASE

-For safe storage of planer and heating element

-Weight: Type 400 = 30 kg, Type 500 = 38 kg, Type 630 = 62 kg